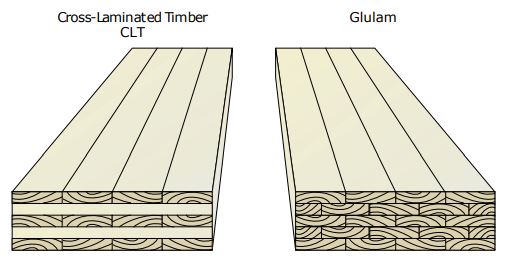

Originating in Germany around the 1900s, glulam was adopted by Australia in the 1950’s but has not reached the same level of popularity as in Europe and North America. The manufacturing process also allows for larger and longer members than would otherwise be possible with traditional solid sawn timber. As a result, the product is stronger than solid timber, and its strength and performance predictions are usually very reliable. They are clamped together under constant pressure until the glue has cured, and before the members are planed, cut to exact size, and sometimes coated with a water repellent sealant.īecause glulam is made up of many laminates, strength-reducing characteristics are often absent or just confined to one laminate. Prior to gluing, the laminates are dressed to exact and uniform thickness.

The laminates are typically finger-jointed into continuous lengths, and available in both softwood and hardwood species. Glued laminated timber, or glulam, is an engineered timber product manufactured by gluing together smaller pieces of stress graded and seasoned timber. Why and how Australia’s poised to building tall timber

#Glulam vs lvl series

This article is part of a series of engineered timber features looking at the advantages and possibilities of mass timber construction, as well as its growing uptake in the Australian building and construction industry.

Ceilings, Internal Wall Materials & Partitioning.

0 kommentar(er)

0 kommentar(er)